1.resin ea phoofolo ea lapengselelekela

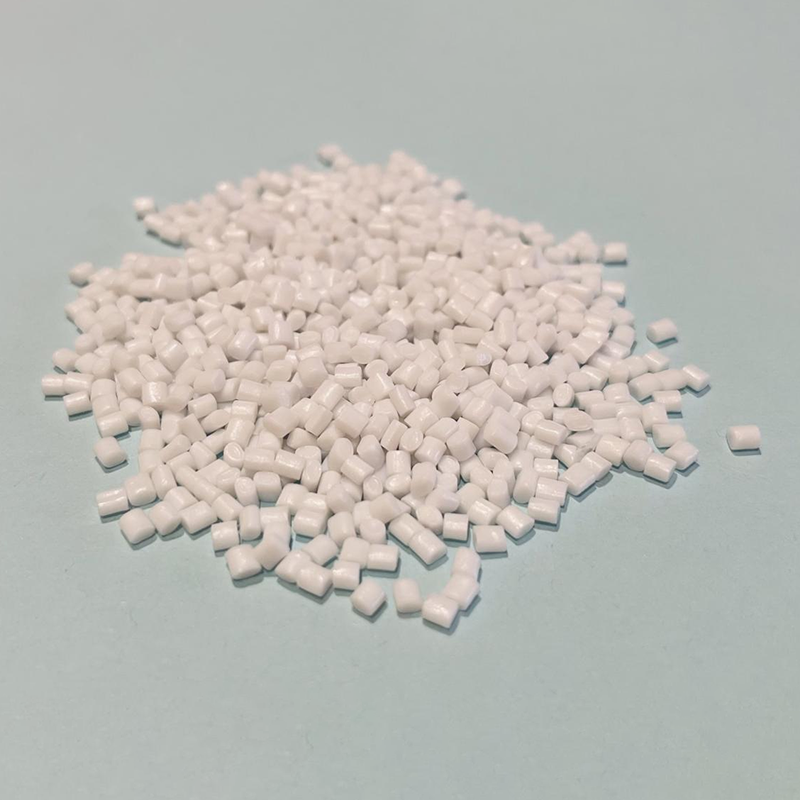

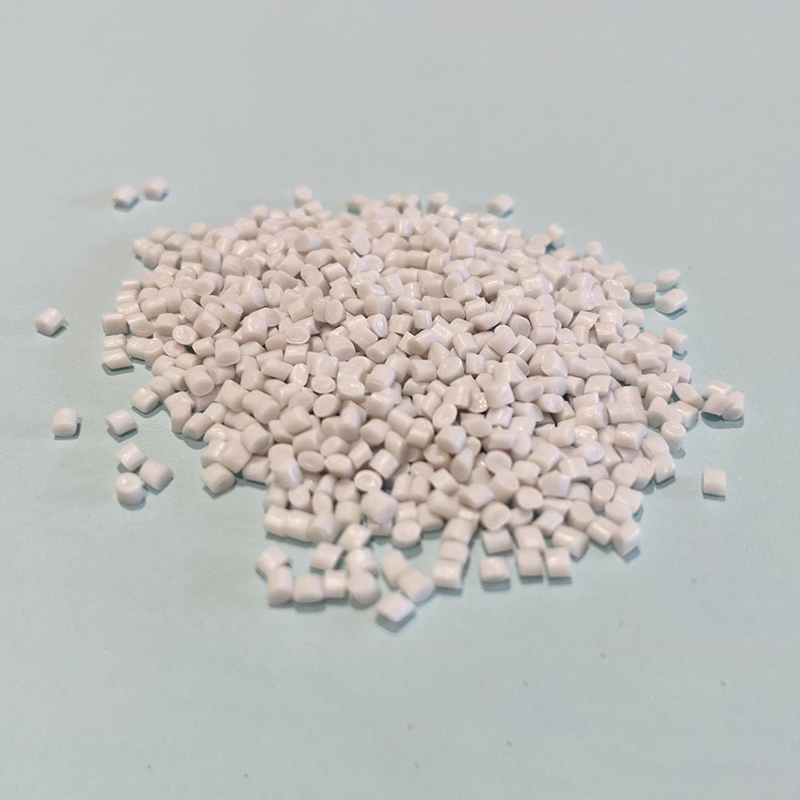

Lebitso la lik'hemik'hale tsa PET Polyethylene terephthalate, e tsejoang hape e le polyester, foromo ea lik'hemik'hale COC6H4COOCH2CH2O.Dihydroxyethyl terephthalate e entsoe ka transesterification ea dimethyl terephthalate e nang le ethylene glycol kapa esterification ea terephthalate e nang le ethylene glycol, ebe joale karabelo ea polycondensation.Ke crystalline saturated polyester, milky white kapa light yellow, polymer e khanyang haholo e nang le bokaholimo bo boreleli le bo benyang.Ke resin e tloaelehileng bophelong 'me e ka aroloa ka APET, RPET le PETG.

PET ke 'mala o mosoeu kapa o mosehla o khanyang, o khanyang haholo o nang le bokaholimo bo boreleli, bo benyang.E na le thepa e ntle haholo ea 'mele le ea mochini mochesong o pharalletseng, mocheso oa nako e telele oa ts'ebeliso ho fihla ho 120 ℃, ho kenya motlakase o motle haholo, leha e le mocheso o phahameng le maqhubu a phahameng, thepa ea eona ea motlakase e ntse e le ntle, empa ho hanyetsa corona ho fokola, khanyetso ea creep, ho hanyetsa mokhathala, ho hanyetsa likhohlano, botsitso ba dimensional li ntle haholo.PET e na le bond ea ester, ho senyeha ho tla etsahala tlas'a ketso ea acid e matla, alkali e matla le mouoane oa metsi, ho hanyetsa li-solvents, ho hanyetsa boemo ba leholimo bo botle.

2.resin thepa

PET e na le khanyetso e ntle ea ho sesa, ho hanyetsa mokhathala, ho hanyetsa likhohlano le botsitso ba sebopeho, ho roala ho nyane le ho thatafala ho hoholo, 'me e na le ho tiea ho hoholo ho thermoplastics: ts'ebetso e ntle ea ho kenya motlakase, ts'usumetso e nyane ea mocheso, empa ho hanyetsa corona hampe.Ho se chefo, ho hanyetsa boemo ba leholimo, botsitso bo botle khahlanong le lik'hemik'hale, ho monya metsi a fokolang, ho hanyetsa li-acids tse fokolang le li-solvents, empa eseng ho qoelisoa ha metsi ho thibela mocheso, eseng ho hanyetsa alkali.

PET resinE na le mocheso o phahameng oa phetoho ea likhalase, lebelo le liehang la kristallise, potoloho e telele ea ho bopa, potoloho e telele ea ho bopa, ho fokotseha ho hoholo ha sebopeho, botsitso bo fokolang ba sebopeho, ho bopa ha brittle crystallization, ho hanyetsa mocheso o tlase.

Ka ntlafatso ea li-nucleating agents le crystallizing agents le fiber fiber reinforcement, PET e na le litšobotsi tse latelang ho phaella ho thepa ea PBT.

1. Thermal deformation thempereichara le mocheso oa tšebeliso ea nako e telele ke tsona tse phahameng ka ho fetisisa tsa polasetiki ea boenjiniere ba thermoplastic.

2. Ka lebaka la ho hanyetsa mocheso o phahameng, PET e ntlafetseng e kenngoa bakeng sa 10S ka bateng ea solder ka 250 ° C, hoo e batlang e se na deformation kapa discoloration, e leng e loketseng ka ho khetheha bakeng sa ho lokisoa ha likarolo tsa elektronike le tsa motlakase bakeng sa solder welding.

3. Matla a ho khumama ke 200MPa, modulus elastic ke 4000MPa, khanyetso ea creep le mokhathala le tsona li ntle haholo, boima ba holim'a metsi bo phahame, 'me thepa ea mochine e tšoana le polasetiki ea thermosetting.

4. Kaha theko ea ethylene glycol e sebelisoang tlhahiso ea PET ke hoo e batlang e le halofo ea butanediol e sebelisoang tlhahiso ea PBT, PET resin le PET e matlafalitsoeng ke theko e tlaase ka ho fetisisa har'a li-plastiki tsa boenjiniere 'me li na le ts'ebetso e phahameng ea litšenyehelo.

Ho ntlafatsa thepa ea PET, PET e ka kopantsoe le PC, elastomer, PBT, sehlopha sa PS, ABS, PA.

PET (e ntlafalitsoeng PET) e sebelisoa haholo-holo ka ho bōptjoa ha ente, 'me mekhoa e meng e kenyelletsa extrusion, blow molding, coating and welding, sealing, machining, vacuum coating le mekhoa e meng ea bobeli ea ho sebetsa.Omisa hantle pele o theha.

Polyethylene terephthalate e lokiselitsoe ka transesterification ea dimethyl terephthalate ka ethylene glycol kapa esterification ea terephthalate e nang le ethylene glycol, ebe joale karabelo ea polycondensation.Ke crystalline saturated polyester, karolelano ea boima ba limolek'hule (2-3) × 104, karo-karolelano ea boima ba 'mele ho ea ho palo ea boima ba limolek'hule ke 1.5-1.8.

Mocheso oa phetoho ea khalase 80 ℃, Martin mocheso o hanyetsa 80 ℃, mocheso oa mocheso oa 98 ℃(1.82MPa), mocheso oa ho bola 353 ℃.E na le thepa e babatsehang ea mochine.Boima bo phahameng.Boima bo phahameng, ho monya metsi a manyane, botsitso bo botle ba sebopeho.Bongata bo botle, ho hanyetsa tšusumetso, khanyetso ea likhohlano, khanyetso ea creep.Ho hanyetsa lik'hemik'hale tse ntle, tse qhibilihang ka har'a cresol, concentrated sulfuric acid, nitrobenzene, trichloroacetic acid, chlorophenol, insolble in methanol, ethanol, acetone, alkane.Mocheso oa ho sebetsa -100 ~ 120 ℃.Matla a ho kobeha 148-310MPa

Ho monya metsi 0.06% -0.129%

Matla a tšusumetso 66.1-128J /m

Rockwell hardness M 90-95

Elongation 1.8%-2.7%

3. theknoloji ea ho sebetsa

Ts'ebetso ea PET e ka ba ho theha ente, extrusion, ho bopa, ho roala, ho tlama, ho etsa machining, electroplating, vacuum plating ea khauta, khatiso.Tse latelang li hlahisa haholo mefuta e 'meli.

1. Mokhahlelo oa ente ① boemo ba mocheso: nozzle: 280 ~ 295 ℃, ka pele 270 ~ 275 ℃, bohareng ba forging 265 ~ 275 ℃, ka mor'a 250-270 ℃;Lebelo la Screw 50 ~ 100rpm, mocheso oa hlobo 30 ~ 85 ℃, hlobo ea amorphous ke 70 ℃, khatello ea morao 5-15KG.② Teko ea dehumidification dryer, mocheso oa tube ea thepa 240 ~ 280 ℃, khatello ea ente 500 ~ 1400 ℃, mocheso oa ente ea 260 ~ 280 ℃, mocheso oa ho omisa 120 ~ 140 ℃, nka lihora tse 2 ~ 5.

2. Sethaleng sa filimi, resin ea PET e tšeloa ebe e omisitsoe pele ho thibela hydrolysis, ebe letlapa le teteaneng la amorphous le fetisoa ka extruder ka 280 ° C ka T-mold, 'me moropa o pholileng kapa pholileng o tima. e boloke e le sebopehong sa amorphous bakeng sa ho sekamela ho thata.Joale letlapa le teteaneng le otlolloa ke tente ho etsa filimi ea PET.

Longitudinal otlolla ke ho preheat lakane e teteaneng ho 86 ~ 87 ℃, 'me mocheso ona, otlolla ka makhetlo a ka bang 3 hammoho le tataiso ea katoloso ea sefofane se teteaneng sa lakane, e le hore sebopeho sa sona se ka ntlafatsa tekanyo ea crystallization ho fihlela mocheso o phahameng: Transverse preheating mocheso oa 98 ~ 100 ℃, mocheso o tsitsitseng oa 100 ~ 120 ℃, tekanyo ea mocheso oa 2.5 ~ 4.0, le mocheso oa mocheso oa 230 ~ 240 ℃.Filimi ka mor'a ho otlolla ka holimo le ka holimo e boetse e hloka ho ba le sebōpeho sa mocheso ho felisa ho senyeha ha filimi ho bakoang ke ho otlolla le ho etsa filimi e nang le botsitso bo botle ba mocheso.

Nako ea poso: Sep-05-2023